Tecnology

A specialized technical office, inside our company.

Design

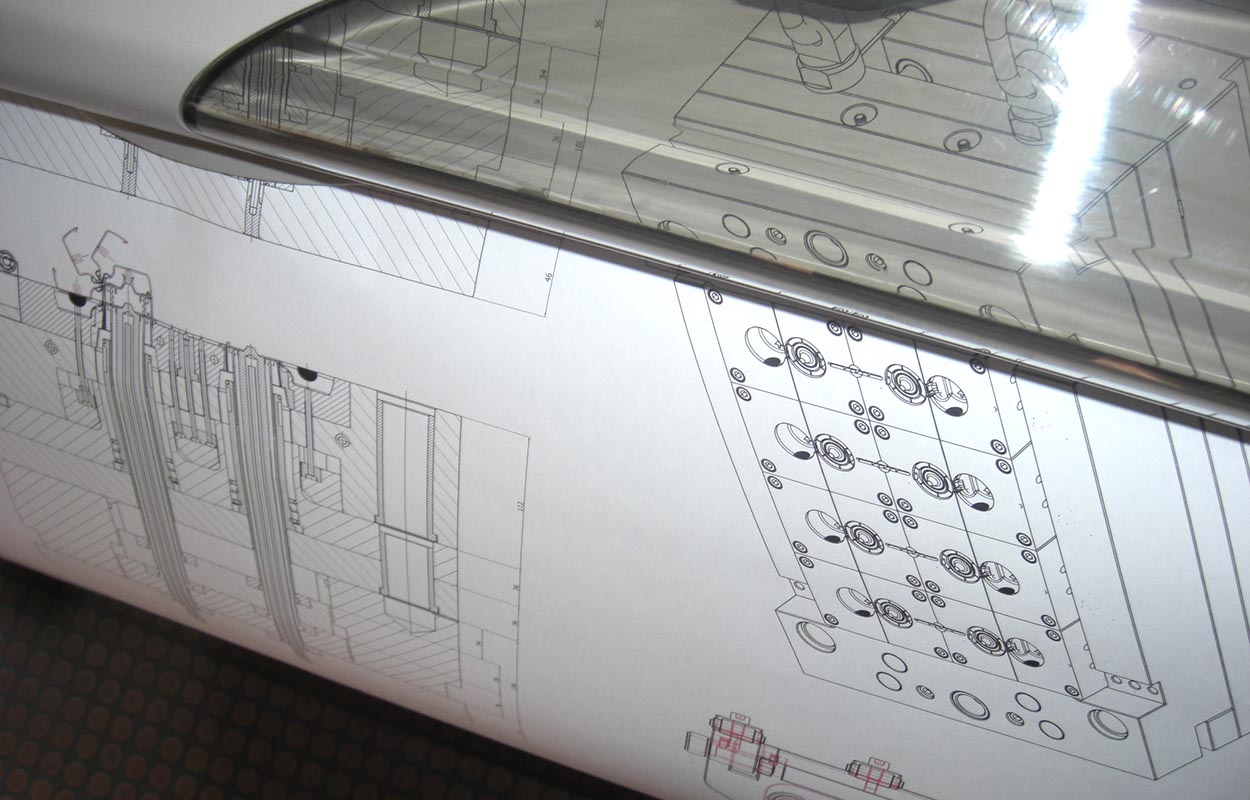

DESIGN

A specialized technical office, inside our company, equipped with the cutting-edge softwares and always up-to-date, guarantees the accurate design of the mold and of the CAM paths.

We consider this a strong point so that the customer can feel in close contact with the Pantostamp designers and establish a relationship of trust and constant collaboration with them throughout the production process.

Manufacturing

MANUFACTURING

The use of the most advanced technologies and systems, together with the use of highly qualified technicians, guarantees the quality of the result and the speed of execution. A production process studied in detail, consistently planned and constantly monitored.

Thanks to the meticulous inspection on all the components of the mold using CNC measuring machines, we guarantee a high precision work aimed at achieving customer satisfaction and expectations.

Spare parts

SPARE PARTS

Pantostamp with the spare parts and molds maintenance service, provides all the necessary support to redesign and build each element to be replaced in the molds with precision and efficiency allowing the customer a quick restart of production and an adequate recovery of the company’s competitiveness.

Test and sampling

TEST AND SAMPLING

Following scrupulous checks after each process and in order to guarantee you an excellent result, after the final assembly a sampling of the mold is made to test and verify its perfect functionality.

If requested by the Customer, Pantostamp offers the possibility of having molding parameters for the production start up as well as customized tests with the Customer’s technicians.

Our workshop

OUR MACHINERY FLEET

WORKSHOP

- ELETTROEROSIONE A FILO Sodick VL600Q 600x400x270

- ELETTROEROSIONE A TUFFO Sodick AG40L 400x300x250

- ELETTROEROSIONE A TUFFO Sodick AL60G 600x400x350

- SPARK DRILLING MACHINE Novotec SD 1014 300x250x350

- CENTRO DI LAVORO VERTICALE A 3 ASSI Quaser MV184 1000x600x500

- CENTRO DI LAVORO ORIZZONTALE Yasda YBM 660N 900x900x700 CON ROTOPALLET

- CENTRO DI LAVORO 5 ASSI RODERS RXP 601 DS 635X540X400 CON AUTOMAZIONE

- CENTRO DI LAVORO 5 ASSI MIKRON HSM 600 ULP 800X600X500 CON AUTOMAZIONE

- FRESA Deckel FP 4M

- RETTIFICA TONDO UNIVERSALE CNC JOnes and Shipmann

- RETTIFICA TANGENZIALE CNC Lodi 1300x600x500

- RETTIFICA TANGENZIALE Bermi 500 500x200x300

- TORNIO CNC Hass SL20

- TORNIO CNC Hass ST20Y CON ASSE Y E MOTORIZZATI

- TORNIO Weiler Matador 150

- TORNIO Schaublin 150

- MARCATRICE LASER LASIT TOWERMARK

TESTING

- PRESSA INIEZIONE IBRIDA NPM 280 (280 ton)

- PRESSA INIEZIONE Negri e Bossi NB80 (80 ton)

METROLOGY

- MACCHINA DI MISURA OTTICA E CONTATTO Zeiss O-inspect

- ALTIMETRO Mitutoyo Linear Height 500

- MACCHINA DI MISURA CONTATTO CNC Mitutoyo Crysta Apex C

- MACCHINA DI MISURA OTTICA Mitutoyo Quick Scope

TECHNICAL OFFICE

- SOFTWARE Workplan (gestione commessa e pianificazione)

- N. 2 STAZIONI Autocad Mechanical 2D

- N. 1 STAZIONE Delcam Powershape CAD 3D

- N. 1 STAZIONE Visi CAD 3D

- N. 1 STAZIONE Powermill CAM 5X

- N. 1 STAZIONE Cimatron E CAD 3D

- N. 1 STAZIONE Cimatron E CAM

- N. 1 Plotter HP A0 – A4

Contact our offices

Office

Via Staffora 14/16

20073 Opera (MI) - Italy

Hours

monday - friday

09.00-13.00 - 14.00-18.00